星形零齿隙联轴器的缺点

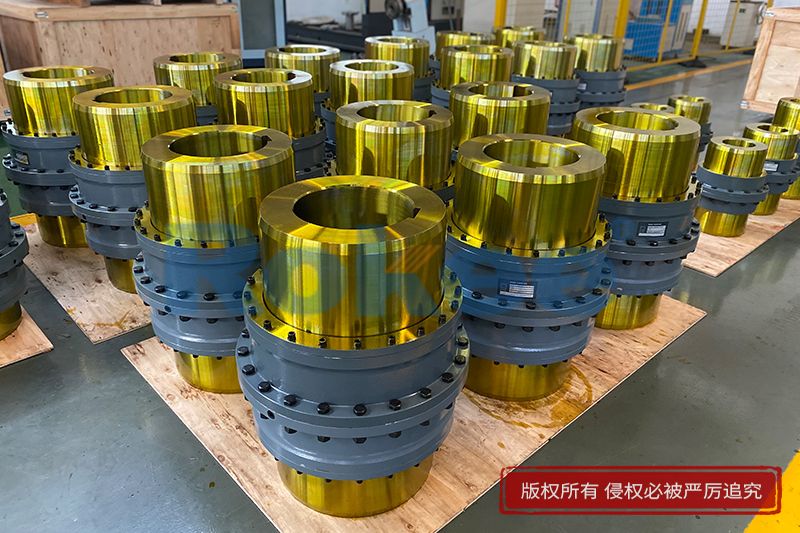

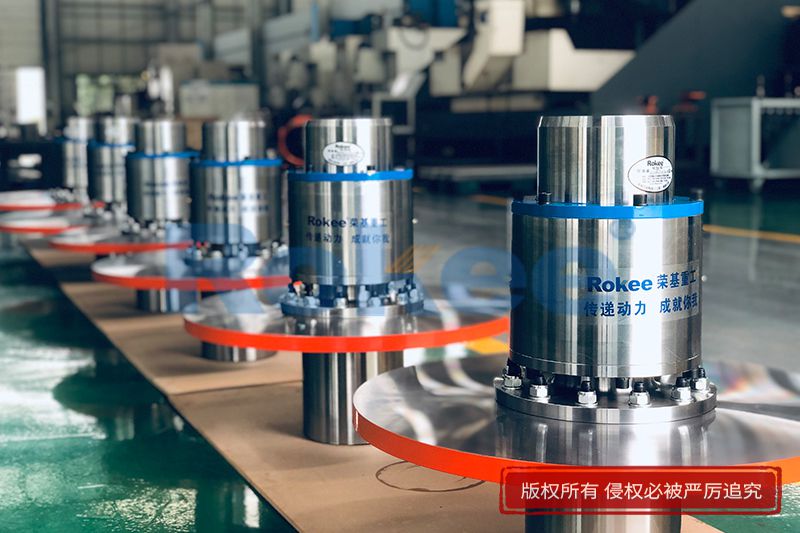

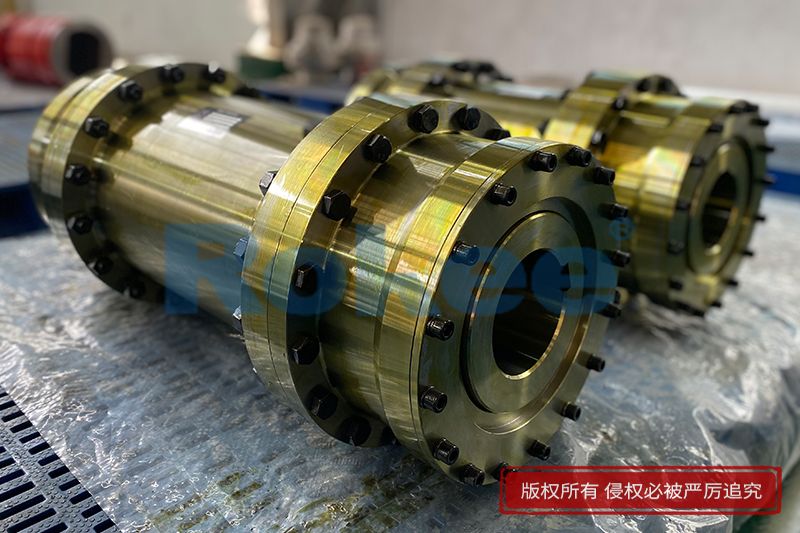

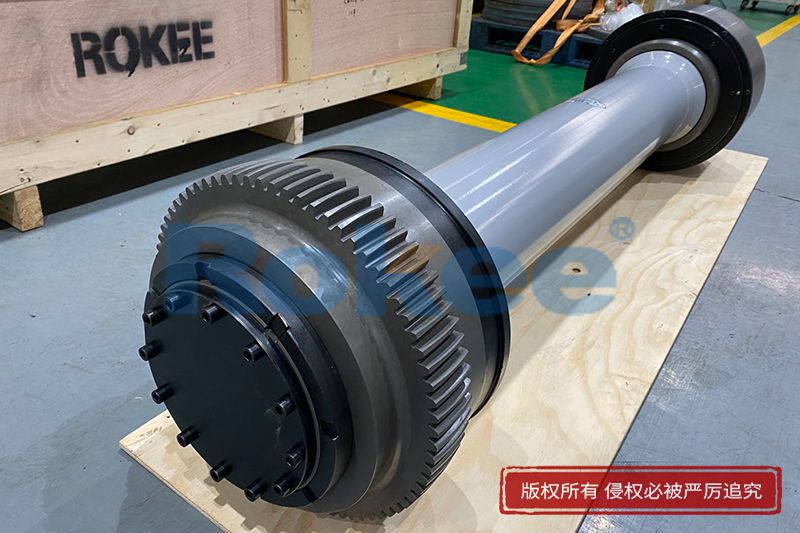

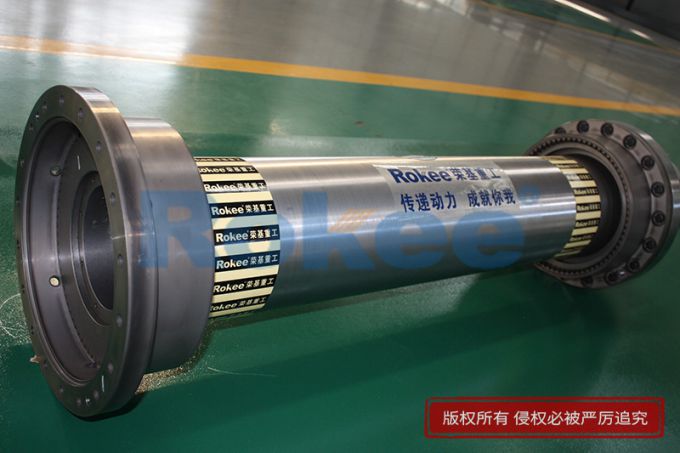

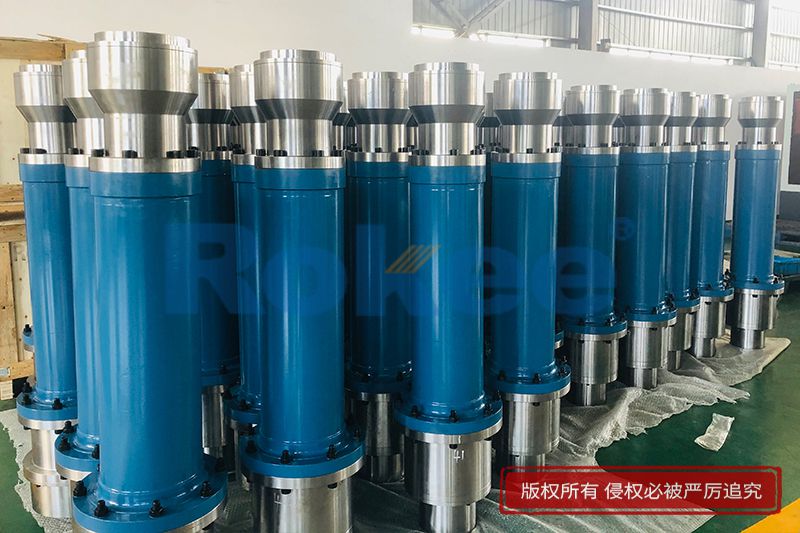

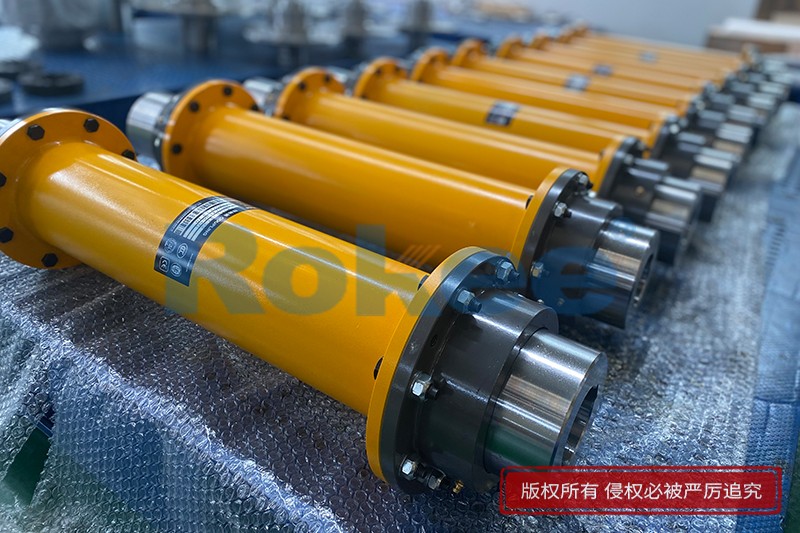

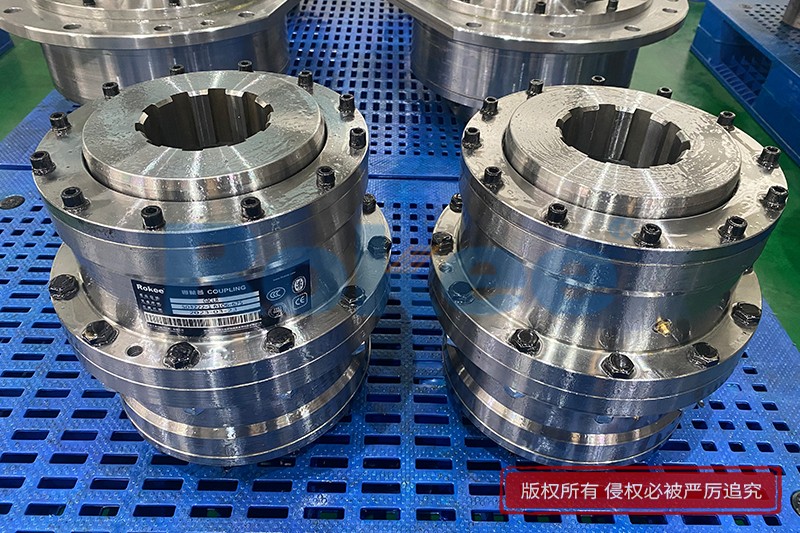

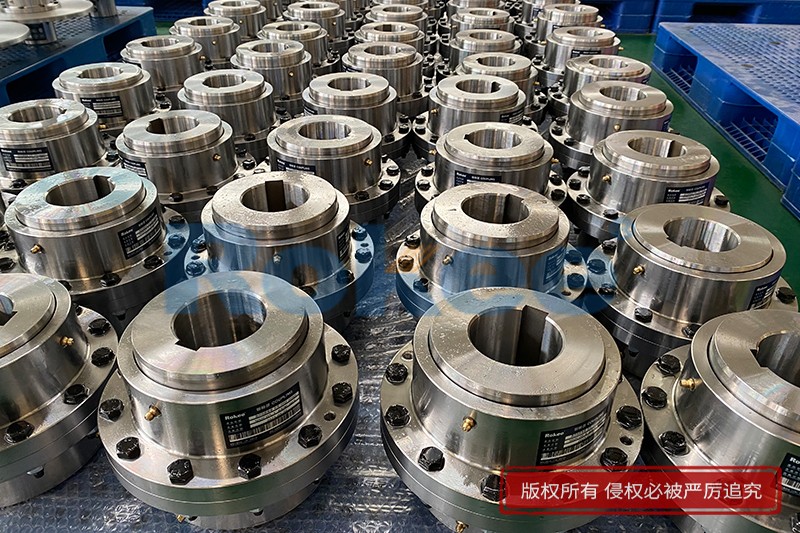

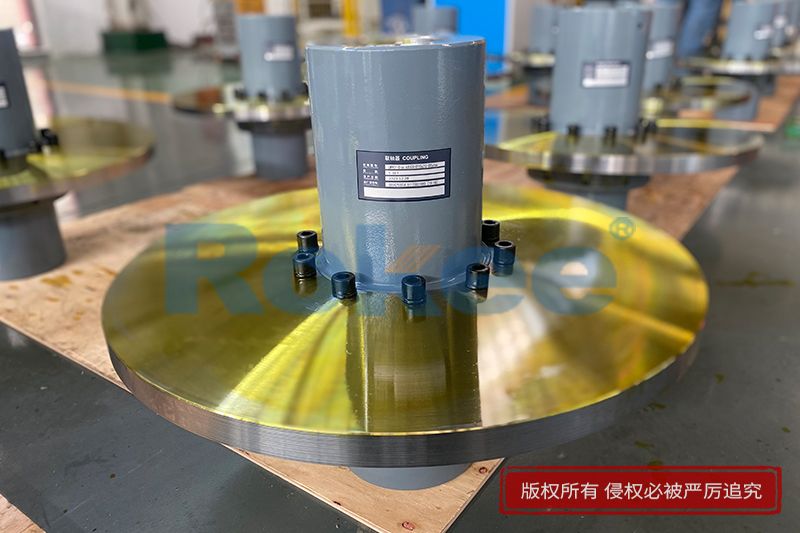

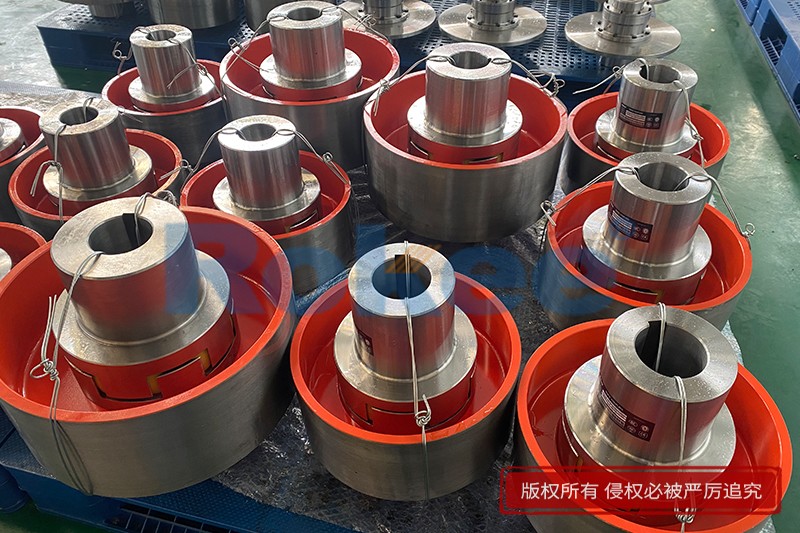

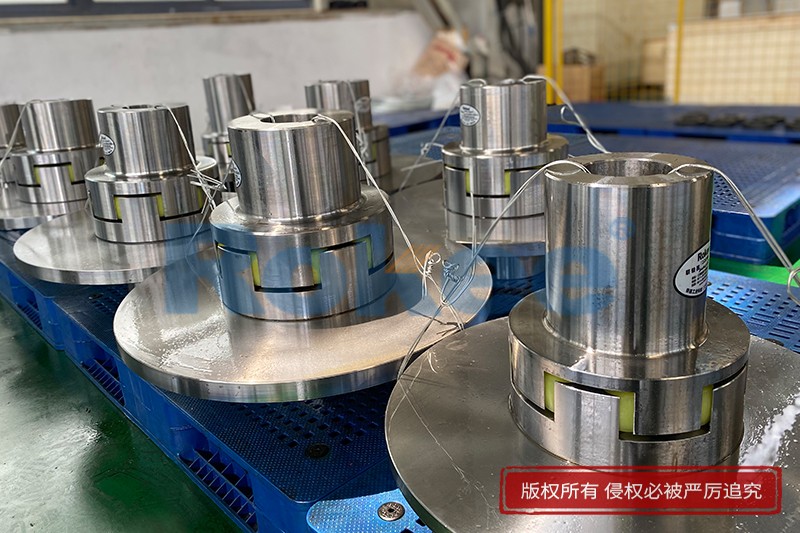

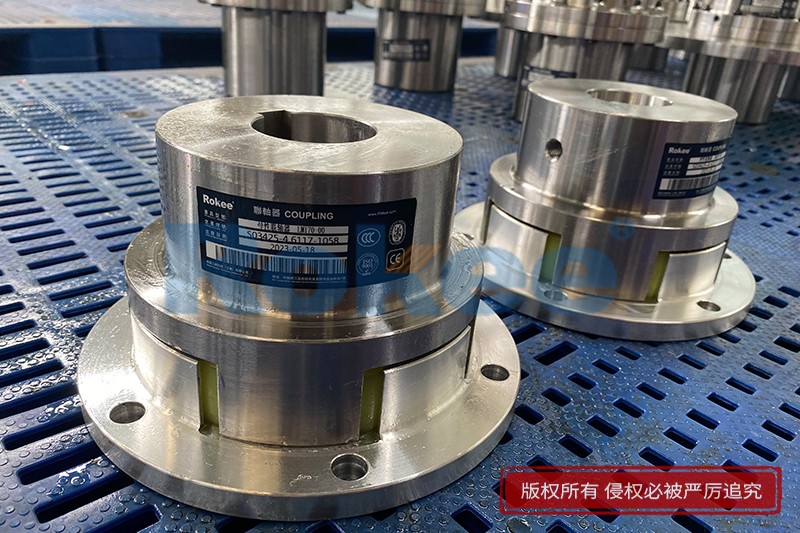

ROD鼓形齿式联轴器是Rokee独立开发的核心技术传动产品之一并且在国家建立和报备了企业技术标准,结合了日本,德国等先进国家的鼓型齿联轴器标准技术,优化了很多细部尺寸链,采用了大压力角齿形设计,轴孔采用短轴设计,缩小了长径比,结构更加紧凑,转速性能优异。相近型号的螺栓采用标准统一化,零部件通用性好。

与国家标准齿式联轴器相比能够传递更大的扭矩,质量相对大幅度减轻,转动惯量小,符合欧洲防爆要求,各种综合性能大大超前。为了更好的传动性能,我们强烈推荐您选用。

鼓型齿式联轴器是一种特别设计的先进齿式联轴器,其外齿制成球面,球面的中心在齿轮的轴线上,齿侧的间隙比一般产品稍大,鼓形齿联轴器可以传递较大的扭矩和允许较大的角位移,性能优异且寿命更加长久。

As the gear type flexible coupling, it can be applied into various general drive sites. Due to the special hook face drum gear design, in the definitive deviation scope, it can effectively avoid the edge stress concentration at tooth meshing, so it has outstanding radial and angular centering capacity. Moreover, it can ensure long service life. ROD series drum gear coupling is one of Rokee’s core technical products. It has compact and reasonable structure, light weight, small hole-position fitting draw ratio, large pressure angle design, accurate centering and excellent speed performance. The bolt design has been standardized in series, the universality of parts is good and its service life far exceeds the one of domestic products.

The gear sleeve at both sides is in the structure of locating ring and uniform parts are used. In addition, the sealing is excellent and easy. Curved-tooth Gear Couplings are applied with larger pressure angle design. The product design is more reasonable and quality is reliable. The gear backlash is reasonable. All ROD series drum type gear couplings are designed in optimization, the structure is more compact and the proportion of hole diameter and length is more coordinated and reliable. Light weight and small rotational inertia. It’s made of high-quality alloy forged steel. It’s very applicable to the sites with anti-explosion requirements. The bolt size of adjacent models is the same and the installation is more convenient. Gear Coupling parts of same model can be exchanged for installation.

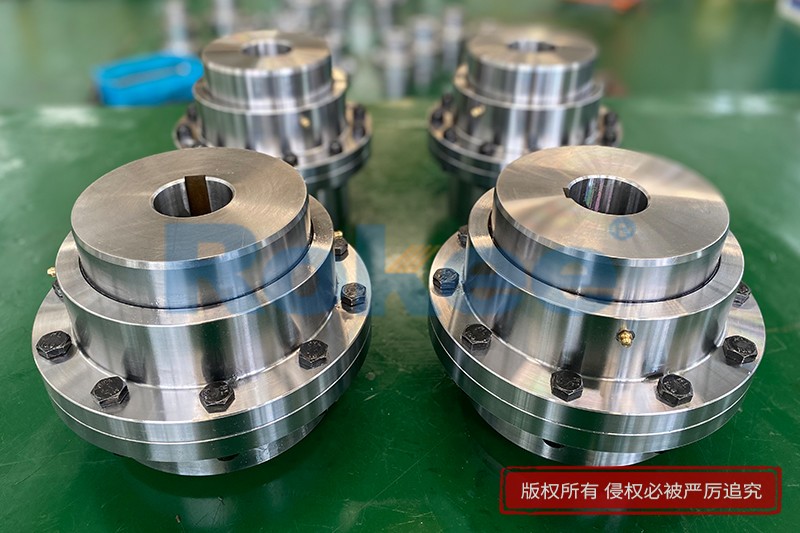

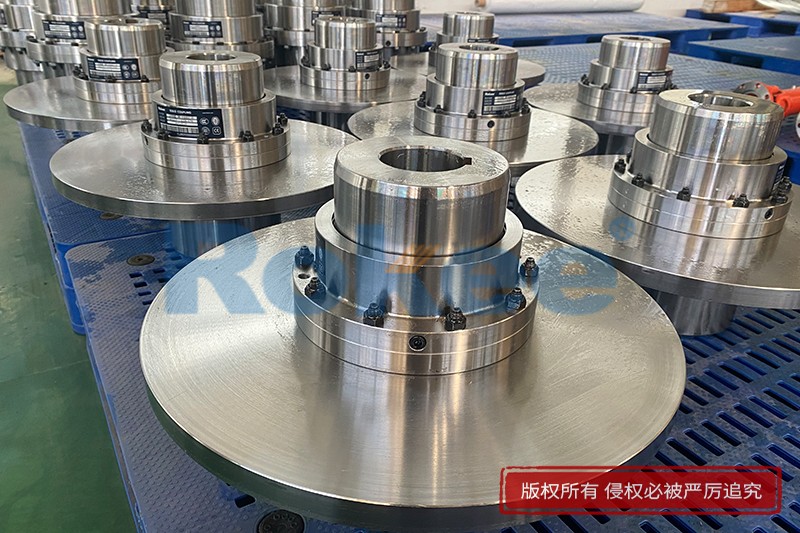

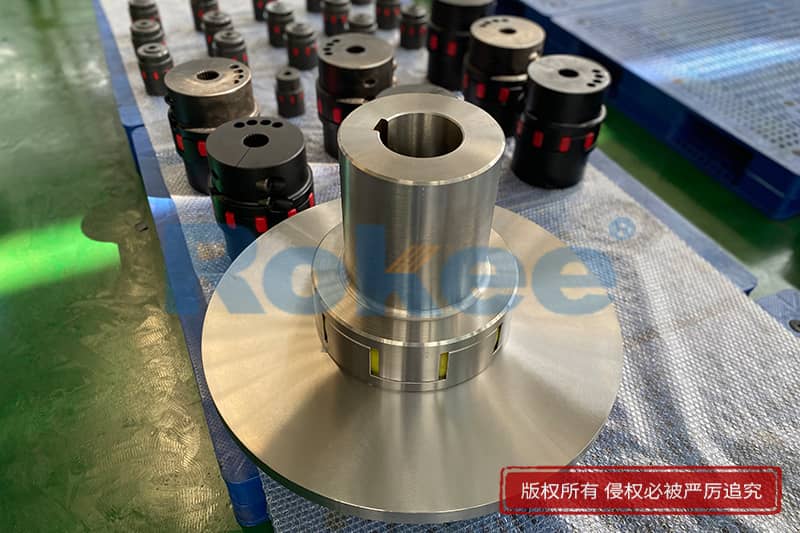

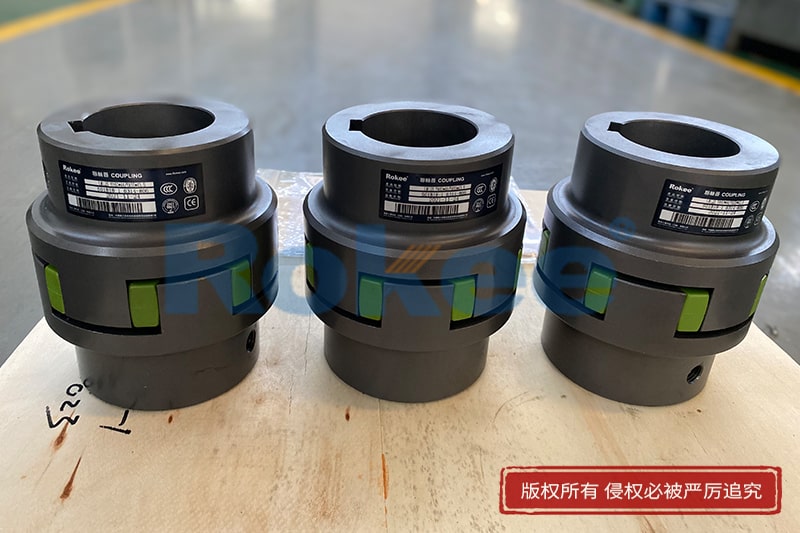

梅花联轴器由两个带凸爪形装的半联和一个硬度可以调整的梅花形弹性非金属元件组成,利用梅花形弹性元件嵌入两个半联之间实现联接,梅花弹性联轴器具有补偿两轴相对位移,减振缓冲,结构简单,无需润滑维护方便等特点。

星形弹性联轴器是以工程塑料作弹性元件,适用于联接两同轴线的传动轴系,星形联轴器具有补偿两轴相对偏移、缓冲、减震、耐磨性能,适应场合普遍,传递转矩20-35000.N.M,工作温度-35-+80摄氏度。星型联轴器聚氨脂弹性体由凸形爪块限制。

梅花形联轴器以聚氨脂塑料为弹性元件与二半联轴器主体紧密组合,主体以进口配方合金铝为主。梅花型联轴器中间聚氨脂塑料元件以独有配方配制,具有耐磨性高抗温性好韧性强,与一般普通塑胶件质量稳定耐用. 梅花型体有六瓣和八瓣,根据客户要求定制. 固定方式有键槽.

爪式联轴器结构简单、无需润滑、方便维修、便于检查、免维护,可连续长期运行。高强度聚氨酯弹性元件耐磨耐油,承载能力大,使用寿命长,安全可靠。工作稳定可靠,具有良好的减振、缓冲和电气绝缘性能。三爪联轴器具有较大的轴向、径向和角向补偿能力。结构简单,径向尺寸小,重量轻,转动惯量小,适用于中高速场合。

The plum-shaped flexible coupling is composed of two semi-couplings with convex claws and a plum-shaped flexible non-metallic element whose hardness can be adjusted. By embedding the plum-shaped flexible element into the two semi-couplings to realize the connection, plum couplings has the characteristics of compensating the relative displacement of the two axes, reducing vibration and buffering, simple structure and easy maintenance without lubrication.

微信客服咨询

微信客服咨询

微信咨询

微信咨询